Article by Buddy Williams

A few weeks ago, I had the pleasure of taking a trip to Nicaragua to visit the operations of the brand ‘My Father’s Cigars.’ This was my first trip to Central America since visiting the Rocky Patel operation in Honduras 12 years ago. I was excited to learn more about the farm, factory and founder behind ‘My Father’s Cigars’ as the brand has become a customer favorite.

We flew into Managua, Nicaragua and took a two-hour bus ride to the town of Estilli, where we stayed in a

My Father’s Cigars are made with a double binder (two tobacco leaves rather than one), that makes them a better-constructed cigar and gives them more flavor.

hotel. It took another hour’s ride to get to the farm, which was located in the countryside outside of Estilli.

Every morning, our group would meet in the company conference room with our tour leader, Jaime Garcia, the son of ‘My Father’s Cigars’ founder Don Pepin Garcia. We talked about what we’d seen the day before, Jaime would answer questions and then he would give us that day’s agenda.

During the trip, we saw the entire operation from seed to cigar. That included the seeds, seedlings, fields, picking, curing, aging, packaging and storage.

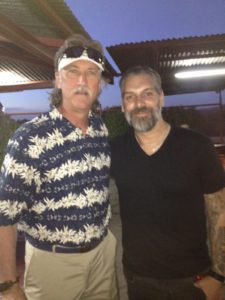

On the last day, we got to meet company founder Don Pepin Garcia and have our picture taken with him.

Here are some interesting things I learned about ‘My Father’s Cigars’:

- The cigars are made with a double binder (two leaves rather than one), which makes them a better-constructed cigar and gives them more flavor.

- The company built a school for employees’ children; runs a health clinic for employees; and has diversified into livestock. They even sell meat to their employees at a discount.

- The company hires between 1500-4000 workers depending on the production schedule and provides transportation to the job.

I think the employees do such great work because the company cares for them so well. And the employees seem to really like their work.

I was amazed at how much labor goes into each cigar – so much so that I wondered how they could make their cigars so affordable. I learned that if company leaders wanted to, they could automate some of their processes and make them faster. But what they want is for the people to have jobs. For example, I saw one lady whose only task was to cut ribbon. They could get a machine to do that but would rather give this job to a person.

The commitment to take care of their employees is a two-way street. I think the employees do such great work because the company cares for them so well. And the employees seem to really like their work. They have two four-hour shifts each day and during those shifts people work hard and the factories are quiet. But during their hour-long lunch break, we saw them talking and smiling. They seemed very happy.

After the tour, I came away with a better understanding of the culture behind the ‘My Father’s Cigar’s company. They put a lot into their employees, who in turn, put a lot into making some of the best and most affordable cigars available.

And that’s why I think ‘My Father’s Cigars’ are so popular with our customers and others around the world.

- The operation of My Father’s Cigar’s is located an hour outside the town of Estelle, Nicaragua.

- During my trip to Nicaragua, I met Pete Johnson, maker of Tatuaje Cigars. Pete works in close consultation with Don Garcia Pepin, owner of My Father’s Cigars, to produce Tatuaje Cigars.

- During the trip, we saw the entire operation from seed to cigar. Here, you see a tobacco field growing between two curing barns.